Katrangan Produk Rinci

| Diameter Obyek: | Kandel≥30mm Dhuwur≤500mm | Gulung Label: | Diameter Batin / Diameter Luar |

|---|---|---|---|

| Sistem Operasi: | Kontrol PLC | Precision: | ± 1mm |

| Label Inner Diameter: | 76.2mm | Diameter Label Maksimum: | 330mm |

Sistem Kontrol PLC Mesin Label Stiker Botol Multiple Jinis

FQA

Q1 , What machines can you produce?

We can produce all kinds of bottles / jars filling machines, sealing machines, capping machines, labeling machines,etc., we can also connect our machines to be various automatic production lines.

Q2 , What materials of your machines are made of ?

According to our clients' different requests, our machines are made of high class stainless steel 304, stainless steel 316 or 316 L, carbon steel, Al alloy, etc.

Q3 , What brands of the electronics and pneumatic parts your machines adopt?

According to our clients' different requests, we can use both domestic brands, joint venture brands and world famous brands.

Q4 , What power voltage do your machines work with?

Usually, our machines work with AC220V 1 phase, 50/60Hz, or AC380V 3 phases, 50/60Hz. We can also make our machines with special voltages, such as, AC 110V, AC415V, etc. So, pase tell us, what is the exact power voltage available in your city before you purchase our machines.

Q5 , Do your machines work with compressed air?

Yes, some of our machines have to work with compressed air, the standard is, 0.6MPa to 0.8 MPa, consumption is various from 0.2 to 0.45 CBM per minute depends on the sizes of the machines. Usually, the users have to prepare an air compressor by themselves in their workshop.

Q6 , What price terms your company can offer?

Usually, we offer EXW or EX-Factory price, we can also offer FOB, CNF or CIF price.

Q7 , What payment term your company accepts?

Usually, we accept T/T or in cash, 40% of the total payment as prepayment / deposit, the remaining 60% will be paid off before we deliver the machines.

Q8 , How long it will take if I put an order of your machines?

The delivery date depends on the sizes and complexity of the machines you order, various from 5 to 50 working days after we receive the prepayment / deposit from our clients.

Q9 , How do you pack your machines before transport / shipping?

Firstly, we clean the machines with anti-rust oil / grease, then, we wrap the machines with anti-moisture plastic film tightly, finally, we pack the machines with solid wood or timber cases that suitable for long distance or sea way transportation.

Q10 , Do you provide the maintenance service?

Yes, we provide maintenance services, because regional difference, we can provide you the services by Email, telephone, express or internet online tools.

Q11 , Is there a warranty and which period of validity does it cover?

We provide one year warranty for all of our machines, the validity time is from the day on which the machines leave our factory to your factory in one year.

Q12 , If any part of the machines broken, how we can get the new replacements?

During the warranty period, if any part broken because of the quality defect or unqualified process, we will send the new replacements to you at our expense. If it exceeds the warranty period, or caused by users' unreasonable operations, or irresistible factors, or any change unauthorized by our company, the clients will have to pay for the new replacements.

Q13 , Is there a specialist to check and test in your factory? On which terms will he be able to start up the equipment in our factory in our country?

Yes, we have specialists to test and check the machines carefully, ensure the machines are at the best state before we transport them to our users. We can send our technicians to your factory to perform commissioning and training your workers. Your company will afford the round air tickets, hotel and foods charges and other necessary charges when our technicians in your city. If our techncians stay more than 5 days, your company will have to pay USD $80 to our technicians each day each person.

And, when the machines are completed,our clients can also send their workers or technicians to our factory to check the machines and learn how to operate the machines.

Sawise didol

1, Insinyur senior sing berpengalaman Range teka ing perusahaan klien kanggo instalasi.

2 , Supply systematic operation training for client workers.

3 , Guarantees all equipment (except human factors) within one year, lifetime maintenance sevices.

4, Sawise klien nggunakake mesin suwene pirang-pirang taun, kita bisa nyedhiyakake program perbaikan kanthi rinci, peralatan asli lan panggantos upgrade perangkat keras lan piranti lunak, ngluwihi umur layanan mesin luwih saka 3-4 taun.

5 , If quality problems arise, the supplier provide technical support and timely supply wearing parts.

FITUR

1, Pengalih umum cocok kanggo diameter botol sing beda, pangaturan cepet lan lokasi sing dikunci.

2, Mesin Coding minangka pilihan, bisa nyithak tanggal, nomer Ora online.

3, Struktur sing dirancang kanthi gampang, cerdas, gampang dijaga.

4, Kacepetan label, nyepetake kacepetan, kacepetan diverter bisa diatur.

5, Gunakake motor merek terkenal sing didhukung, pasokan label stabil lan andal.

6, sistem kontrol PLC, kabeh mesin bisa stabil kanthi kecepatan dhuwur.

7, inspeksi Photoswitch kanggo njamin ora ana botol, ora ana label; ora ana label, autocorrection lan alarm.

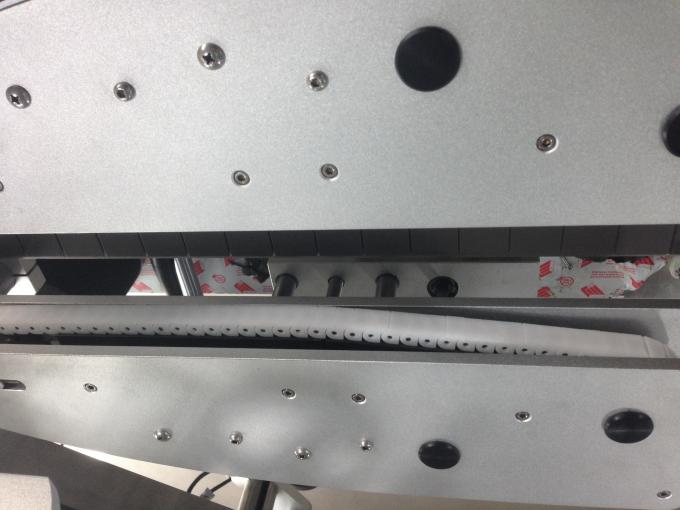

8, Gunakake sabuk katun katahanan supaya labeling lancar, ora dilipat, kualitas labeling luwih apik.

Lamaran

1, Diameter njero label yaiku 76.2mm, diameter njaba maksimal 330mm.

2, Mesin kasebut ditrapake kanggo Industri Bahan Kimia lan Panganan Saben Dina,

3, Lebar maksimal label 190mm (bisa diangkat miturut sarat).

4, diameter Botol Kandel luwih gedhe utawa padha karo 30mm, dhuwure kurang saka utawa padha karo 500mm.

Parameter Teknis

| Kacepetan produksi | 45m / menit |

| Akurasi label | ± 1mm |

| Lebar maksimal label | 190mm (bisa diangkat miturut sarat) |

| Dhiameter botol | Kandel≥30mm dhuwur≤500mm |

| Label diameter tengah | 76.2mm |

| Label diameter njaba | Max330mm |

| Ukuran garis gedhe | L2000 × W700 × 1400mm |

| Bobot | 380KG |

| Nggunakake kekuwatan | 220V 50HZ 1500W |

Kaluwihan

1, Umume komponen digawe dening papan samping aluminiumofanodizing3.0, nglereni bobot lan nglereni biaya transportasi.

2, Kacepetan maksimal produksi udakara 45m / menit. Akurasi label yaiku ± 1mm.

3, Mesin nggunakake tenaga, ukuran, Bobot disesuaikan.

Rincian

Tag: mesin labeler otomatis, mesin label botol